Quality

Exceeding customer expectations with excellent quality

Dedicated to quality control at every step

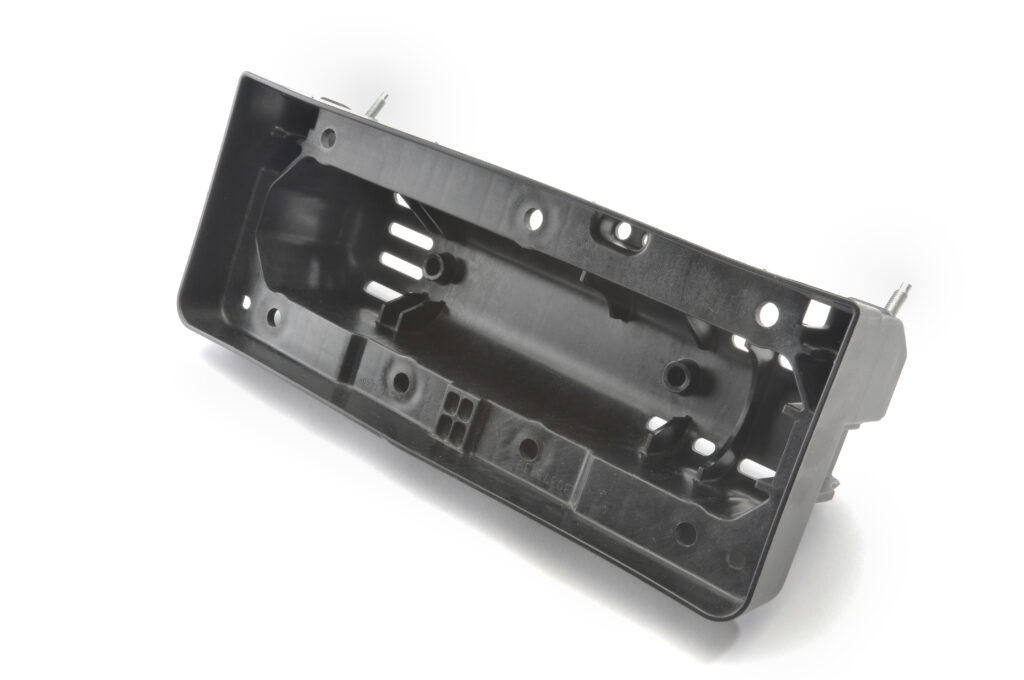

As an organization, we are dedicated to our quality systems and exceeding our customer’s expectations. Our primary focus is on enhancing product and service quality and value to ensure customer satisfaction. We have been honored with several quality achievement awards for our commitment to this goal.

Our trained quality control personnel are in place to ensure that your products are produced with all critical part characteristics within specification. Our specialized quality engineers have plastics engineering backgrounds and utilize a systematic approach to problem solving to provide quick problem resolution.

In order to keep quality at the centerpoint of every project, we have a dedicated program manager, customer quality engineer, launch support with samples, tuning, part print development, and 24-hour customer support for on-site maintenance.

CMM Management

We use Coordinate Measuring Machines (CMM) to assess the dimensional accuracy and geometric characteristics meet specified tolerances and quality standards.

SPC Tracking

Statistical Process Control (SPC) tracking monitors and analyzes the production process in real-time to remain within specified parameters and produce high-quality parts.

Color Matching

Color matching combines technical expertise, precise measurement, and careful control of processing parameters to achieve accurate and consistent results.

Post-Mold Error Proofing

We identify and mitigate potential defects or errors in the manufactured parts to ensure only parts meeting specified standards are passed.

Lab Testing

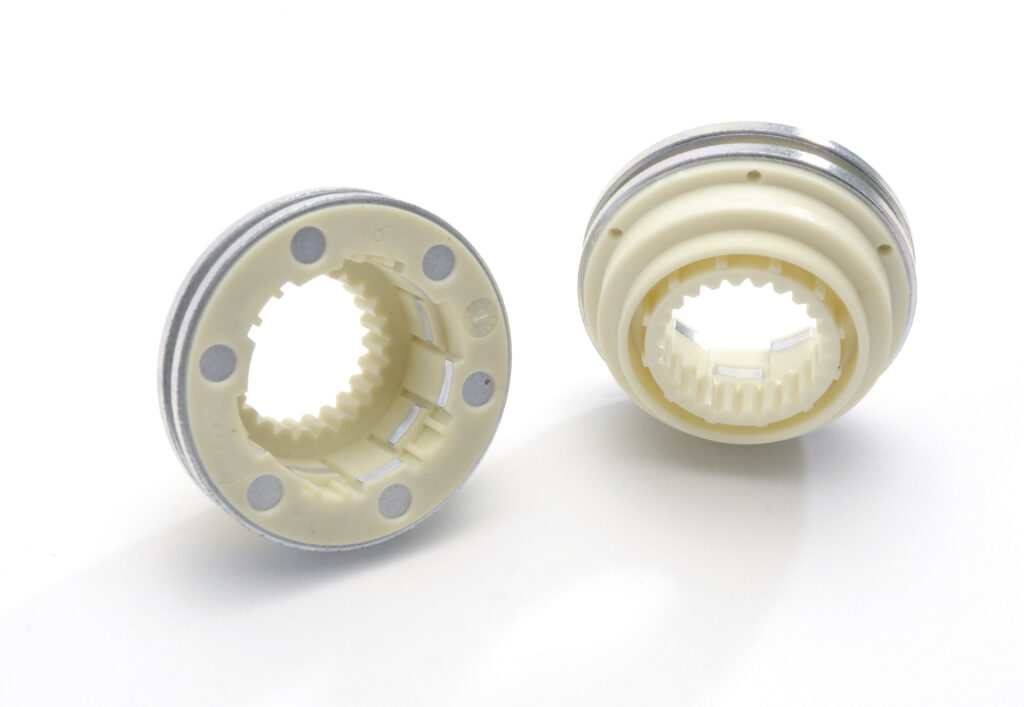

Lab testing, including tensile and torque testing, evaluates the mechanical properties and performance characteristics of molded plastic parts.

Vision Systems

Vision systems, also known as machine vision systems, use cameras, sensors, and image processing software to capture, analyze, and interpret visual data.

In-Mold Sensoring

We embed sensors directly into the mold cavity or tooling used in the injection molding process to collect real-time data about various process parameters.

IATF 16949 Certification

IATF 16949 Certification demonstrates our ability to consistently provide products and services that meet customer and regulatory requirements.

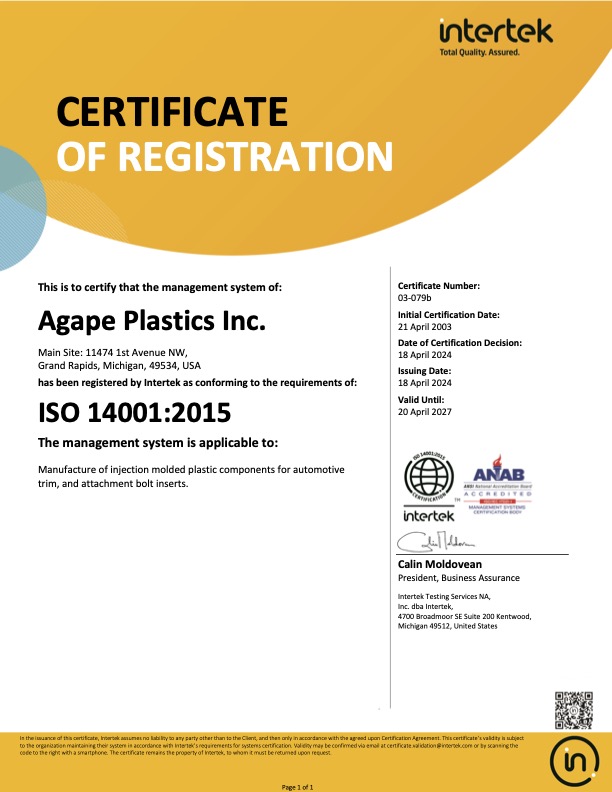

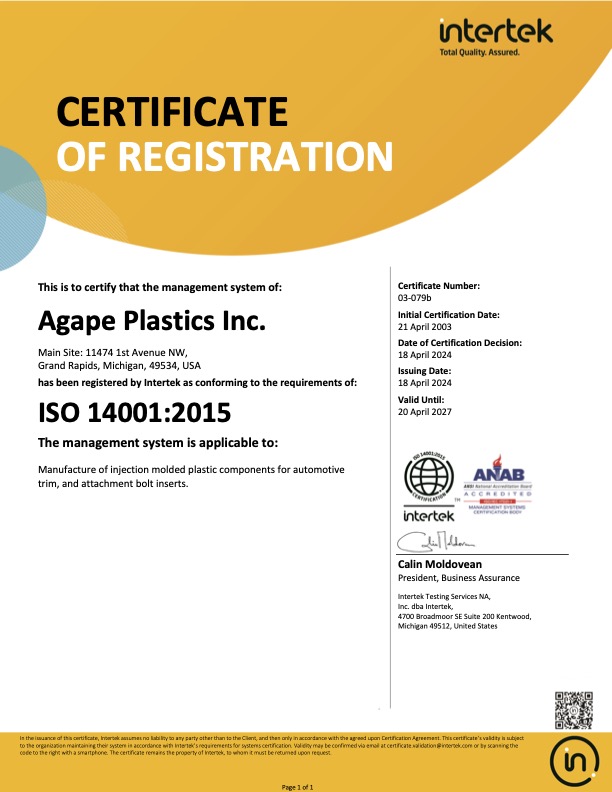

ISO 14001 Certified

This certification proves we have implemented an Environmental Management System (EMS) that complies with the requirements of ISO.

PPAP

Following the Production Part Approval Process (PPAP), we minimize the risk of defects, reduce variability in production processes, and establish confidence in product quality.

APQP

Advanced Product Quality Planning (APQP) is a proactive approach to ensure that quality is built in from the design phase through production and delivery.