Post-mold Assembly & Value-added Operations

Taking your part from start to finish

Saving you time and money with value-added operations and services

Value operations in the plastic injection molding industry are focused on maximizing value for customers by delivering high-quality products efficiently and effectively while continuously striving for improvement and innovation.

Providing a variety of post-mold assembly capabilities

Using our experience with various online and offline assembly operations, you can count on us to provide a high-quality part. From manual assembly to automated work cells, we’re more than just a plastic injection molding company.

- Assembling weather strips

- Agapé performs different online/offline assembly processes

- KIT assembly

- Snap-fit assembly

- Assembling foam, u-clips, push nuts, grommets

- Adding a paper barcode/2D barcode to parts

- Assembling wire harnesses

- Assembling springs

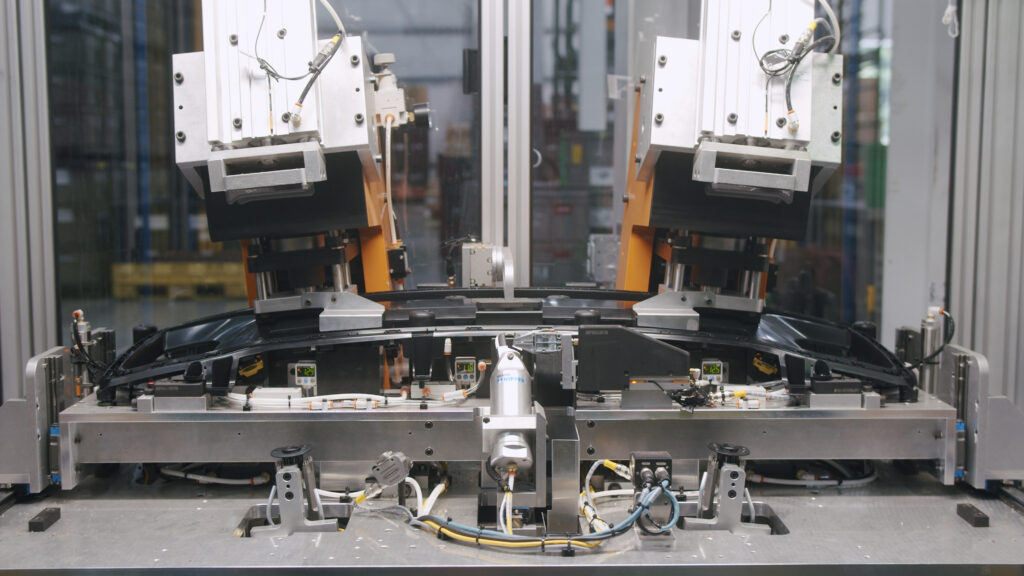

Plastic welding techniques for best applications

Agapé Plastics performs both sonic welding and heat-stake welding to fuse two plastic parts together. These processes offer strong bonding at the molecular level. Sonic welding utilizes high-frequency sonic vibrations to create frictional heat between the parts being joined. Heat-stake welding is often used for larger parts, and uses both heat and pressure to soften a specific area of the plastic enough to be remolded into a new shape or profile that forms over or around the connecting part.

Error-proofing equipment design and build

We are always looking for ways to reduce errors to improve quality, reduce waste and costs, and remain globally competitive. Error-proofing is a method of 100% inspection at the source, rather than down the line. At Agapé, we use specialized equipment for assembling components to prevent misassembled products from being shipped to our customers. By implementing fail-safes in the fixture, tooling, programming, and machining processes, errors can be quickly identified and defective parts removed from the process before they cause greater problems down the line.

In-house tool room for quicker repairs

Local tool vendors are used to build all of Agape’s injection molds. We choose to outsource all of our injection mold builds for faster turnaround times, quality control, and enhanced communication. When a tool needs repair, our internal team of experts can perform repairs right here on-site to keep the machine running.

In-house CMM machine for quality control

We use a Coordinate Measuring Machine (CMM) to assess the dimensional accuracy and geometric characteristics meet specified tolerances and our customer quality standards. Parts are measured both pre- and post-production for quality control measures, testing, and to prevent components that are out of tolerance.

Request a quote today

Whether your project needs engineering support, tool build assistance, or just injection molding production, we have a full team ready to assist you from start to finish.