Engineering

Work with a specialized plastic engineer

Offering all the advantages of in-house engineering

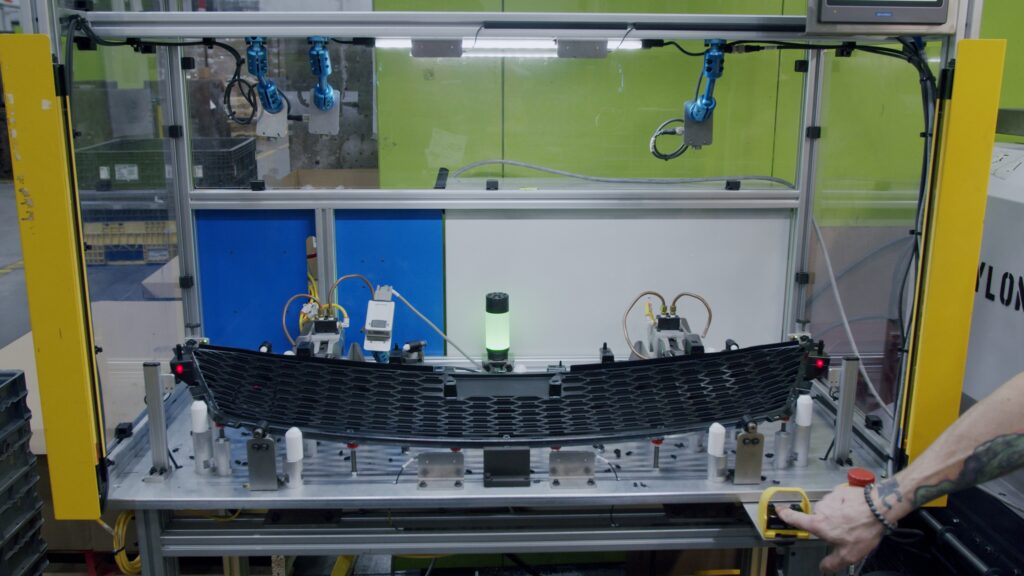

Our team of plastic engineers have decades of combined experience using thermoplastics to create a high quality plastic component. From plastic injection molding to insert injection molding, we will analyze your project requirements and offer a variety of solutions to create a cost-effective solution that meets all specifications and premium quality.

Complete program management

Our complete program management process offers you a dedicated project engineer/program manager to take your part from concept to quoting, to building the injection molding tool, and then to mass production. Our highly skilled engineers are involved in developing prototypes, designing and building injection molding tools, vendor management, launch activities, implementing secondary operations, and more.

VA-VE activities

We offer both value analysis (VA) and value engineering (VE) services to our clients. With an eye toward your best value on the bottom line, we use value analysis with existing products to analyze and evaluate to reduce costs, improve product function, or both. Value engineering ensures that during product development, we focus on reducing costs or improving function (or both) by way of product evaluation and analysis. This takes place before any capital is invested in tooling, raw materials, or equipment.

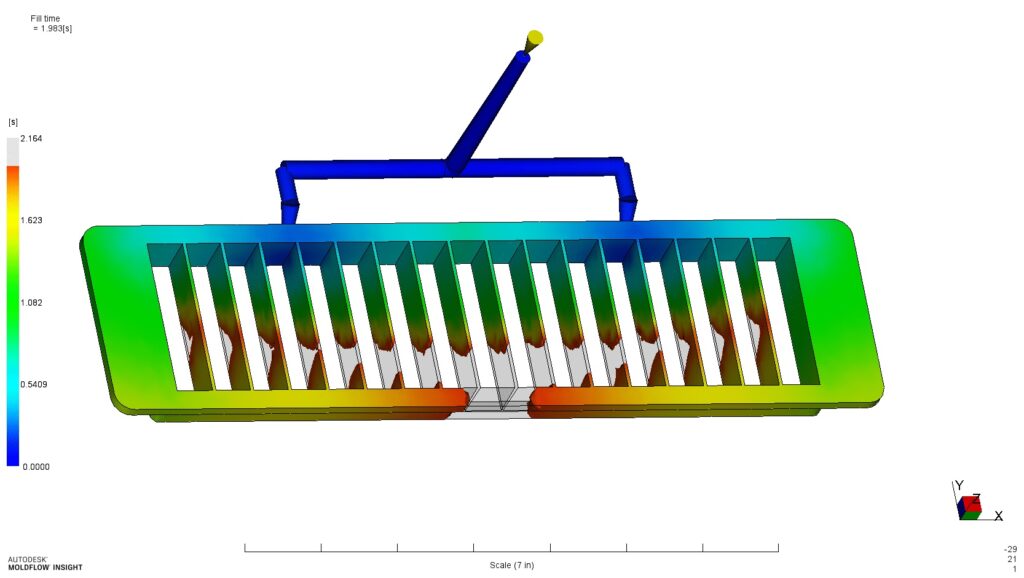

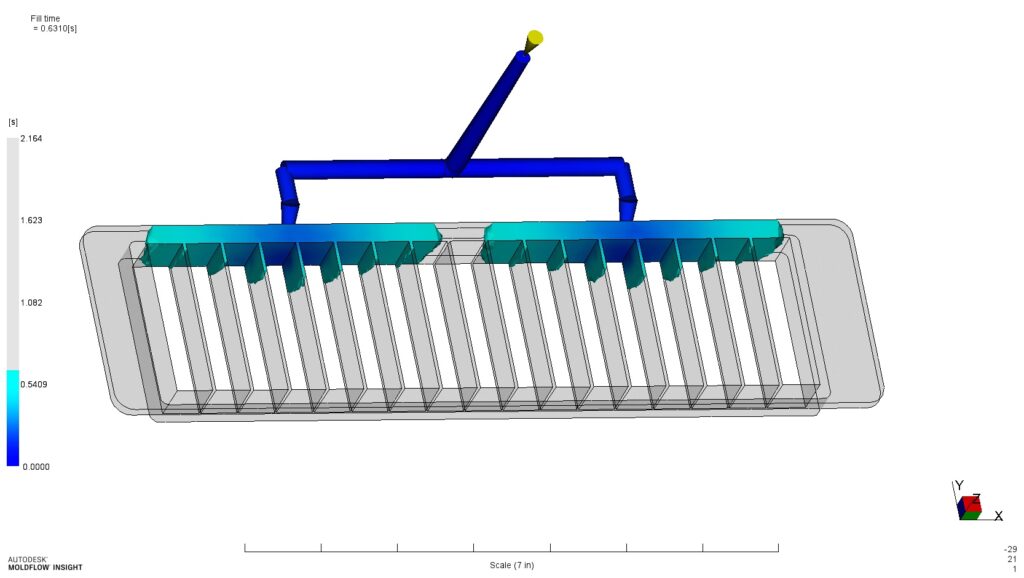

Part design feasibility analysis

While our team is not part design responsible, we do work closely with customers to assess current part designs and evaluate if they are feasible to manufacture. Bring us your drawings and we can work together to ensure the best solution.

Metal to plastic engineering

Taking a metal component and converting it to a plastic component is not an easy task. Utilizing a thermoplastic material offers production flexibility, cost-effectiveness, and lighter solutions as opposed to a metal material.

Part design optimization services

If you have a part design that’s not feasible to manufacture, work with our team to enhance your part. We can get started down the right road to offer design suggestions, how to improve the design, and make it more cost-effective to produce.

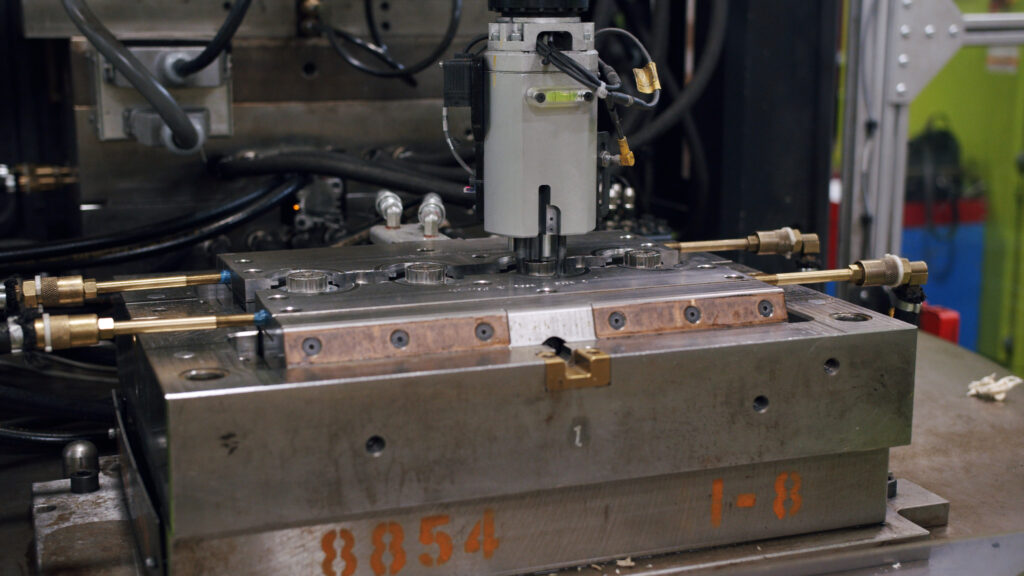

Tool design and build process

While we don’t build our own injection molding tools in-house, we strategically outsource all of our injection molding design and building. With the support of our trusted local tooling vendors, we will help design and build an injection mold that is completed on time, in budget and that will produce a high quality plastic component.

Request a quote today

Work with our dedicated plastics engineers to get a custom quote for your project.