Custom Insert Injection Molding

Consistent production outcomes

Personalized solutions bring your project to life

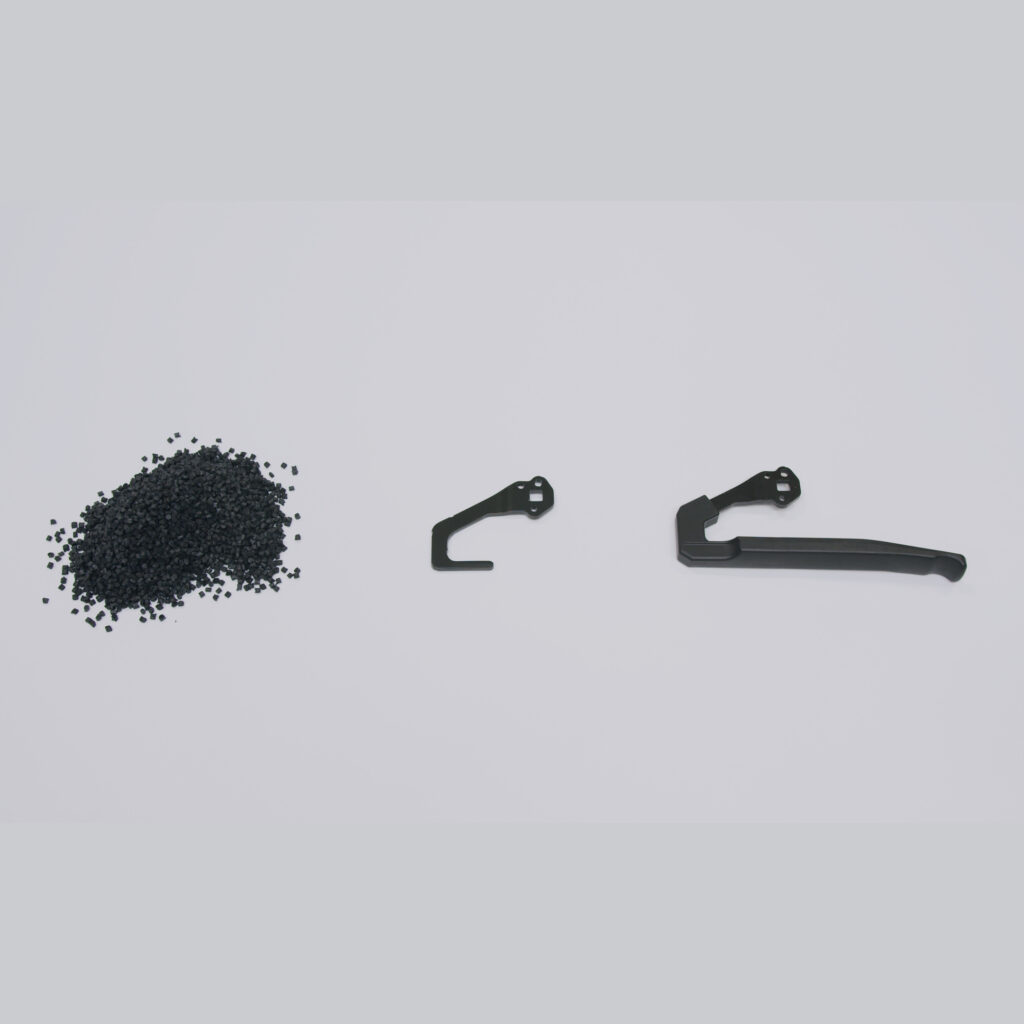

Custom insert injection molded solutions offer flexibility, alternative assembly options, and a variety of cost-saving activities. Our injection molding machines and quality equipment allow us to adapt quickly to industry advancements. Polymer technologies and molding processes have led to new products and processes.

With custom insert injection molding, part design plays a critical role as the plastic and insert are mechanically bonded together. Since there is no chemical bond between the insert and plastic, the design must be properly evaluated for manufacturing feasibility.

With the help of Agapé Plastics, we can ensure your part design is optimized and will meet performance expectations in the application.

What is insert injection molding?

Insert injection molding is the process of molding or forming plastic parts around non-plastic parts (referred to as inserts). The inserted component is usually a thread or rod to add strength to the final piece. Most of the time, we combine metal and plastics into a single unit.

What are the advantages of insert injection molding?

We’re looking for improved wear resistance, tensile strength, and weight reduction when we use engineering plastics and we use metallic materials for strength and conductivity. Additional benefits include:

Improves component reliability

Improved strength & structure

Reduces assembly and labor costs

Reduces the size & weight of the part

Enhanced design flexibility

Insert injection molding machines at Agapé

- Vertical machine ranges from 110T to 340T

- 46 injection molding machines total (both horizontal and vertical machines total)

- Ability to mold with most thermoplastic materials

- Agapé currently molds with materials such as thermoplastic olefins (TPO), polyphenylene (PP), nylon, acrylonitrile-styrene-acrylate (ASA), and more

- Agapé utilizes material with different fillers and additives: glass-filled, talc-filled, impact-modified, etc.

Agapé provides insert injection molding to these industries

Automotive

Agricultural

Appliance

Furniture

Hand tools

Large (semi) trucks

Renewable energy

RV, marine and power sports

Request a quote for custom insert injection molding

We assess insert injection molding processes and raw material options to ensure maximum product quality, process efficiency, and cost competitiveness.